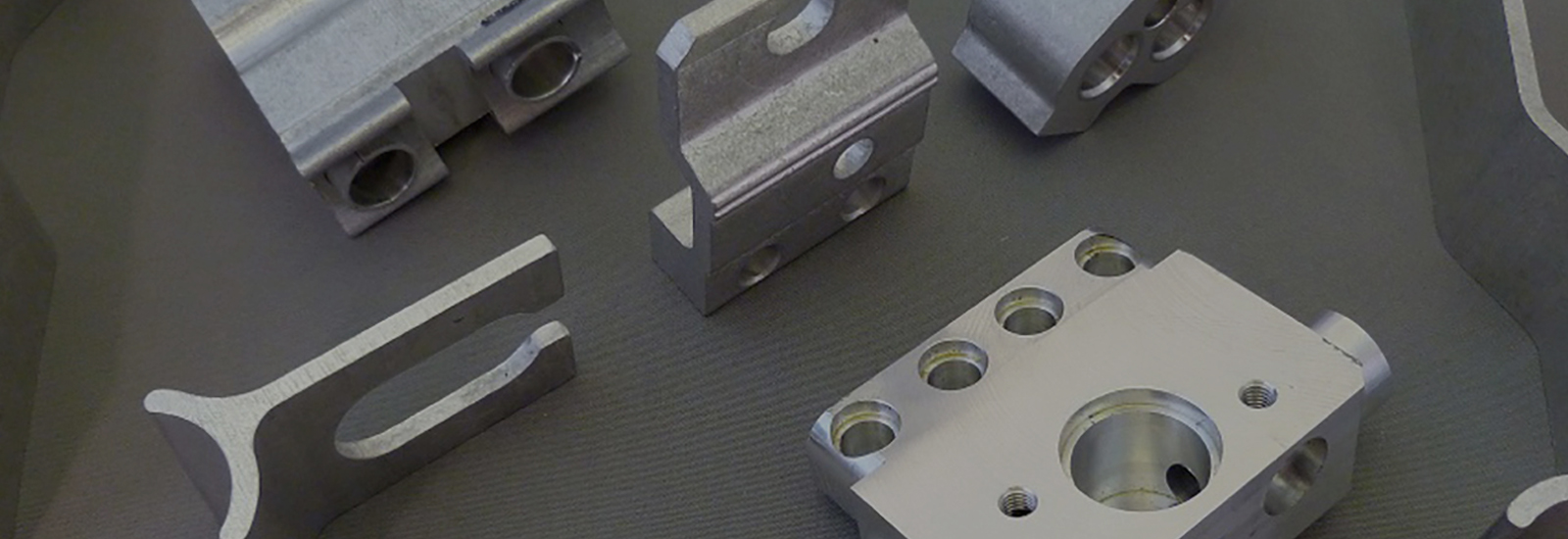

What we do

We manufacture a wide range of parts and assemblies for industries spread over a wide spectrum.

Agriculture Equipment

Alternate & Green Energy

Government

Automation

Construction and building materials

Chemical

The company has started in 2005 manufacturing small precision components. With new concept and development, we renewed in 2015, from conventional lathe to CNC, VMC machines for Customer’s precision part demand. Increased customer demands, for advanced and complex machining requirement, forced us to introduce state of arts CNCs, and VMCs machines.

- To be and remain the customer’s first choice.

- Adapt advance and latest technology.

- Cultivate lean and flexible manufacturing culture.

- Delight our customers with continual improvement in Quality, cost and service.

- Prompt Delivery

- Large Production capacity

- Maximum customer satisfaction

- Cost Effective Price

- We Gives You Quality Assurance

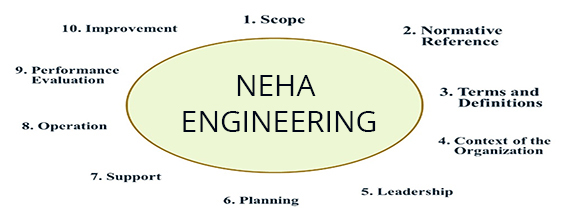

Quality

Our prime motto to produce componets with continously controlled and monitored process with highest quality Satndards to achieve critical parameters within closest tolerances consistently to match customers satandards.

View More

View More

Safety & Environment

We at Neha Engineering are committed to provide a safe and hygienic working environment for our staff while also striving to ‘do our part’ for the environment around us.

- Oil mist collection.

- Safety wear for feet, eyes, ears, coveralls.

- Chip guards.

- First aid equipment and certified staff.

- Adequate lighting, heating and ventilation

- Oil mist collection.

Safety and shop environment

- Reducing paper use.

- Using recycled packaging materials.

- Efficient coolant recycling & management.

- Reducing paper use.

Doing our part

Our qualified professionals offer a variety of services

- Designing and Consultation

- Tooling and test fixture manufacturing

- Assembling

- Production saw cutting